AIR BLASTER

What is an Air Blaster ?

An air blaster is a contraption that facilitates bulk material handling in storage containers like silos and bins .It releases blasts of air to free trapped build-ups of material and forces them to flow. It provides the solution to the two common issues affecting containers like silos — rat holing and bridging. In bridging, material becomes wedged across the outlet and will not move, thereby blocking outflow. With rat holing, the central column of material collapses through the outlet, while materials remain stuck to the sides and do not flow. Air blasters can blast away the build-up and allow the materials to flow smoothly again.

Blasting Away Material Build-Up

Air Blasters are most useful in edged containers, wherein materials have the tendency to drift to the corners and get stuck. Acting almost like an explosive, the Air Blasters can blast the corners to loosen the material and force it through the outlet. This gets rid of the need for a technician to physically strike blows on the container, or enter it, to loosen out the material. This makes the working environment safer and more pleasant.

CONCERNS & SOLUTIONS

Material Build-Up

As the bulk material flows, via the different means, various shapes keep forming within it. While some facilitate its flow, others restrict and even choke it off. The common flow-shapes that impede the bulk material’s flow are named after their shapes and include Arching, Bridging, Funnelling and Rat-holing. These impediments, to smooth material flow, seriously affect cement & other process industries, as well as power industry the world over.

Concerns

Flow related problems, such as coating or jamming, affect cement plants all over the world, especially in their high temperature parts like Cyclones, Feed Pipes, Riser Ducts, Smoke Chambers, kiln inlet and coolers. Similar problems are further complicated in areas like gypsum/ limestone hoppers and coal bunkers, where the temperature is normal but there is high moisture and fineness.

Materials stored in bulk quantities in bunkers, hoppers, bins and silos, face material build-up problems. Thermal power, steel, chemical & fertilizer plants, coal washeries, etc. face these jammings often, which adversely affects the productivity of not only the plant, but the people operating and maintaining these plants as well.

Solutions

In the past, the standard practice was to get rid of these coatings/ jammings through manual poking, or some other mechanical methods like vibrators. However, these ways and means lacked the effectiveness and efficiency, as well as were hazardous. Thus, these rudimentary methods were inadequate in solving the material build-up problem. MM Overseas’ MM Air Blaster systems came as blessing for the bulk material handling industry, which turned out to be a completely new and ingenious engineering solution to jamming/ choking problems. Air Blaster systems are not only safe and easy to maintain, but very rugged and reliable too, even over extended period of time. At the same time, these systems are extremely effective and efficient.

With immense experience in the domain, we are instrumental in offering a wide assortment of Industrial Air Blaster to our most valued clients. Our products are fabricated from quality raw material and that is procured from reliable vendors of the market.

OPERATIONS

Operation of Our Air Blaster Systems

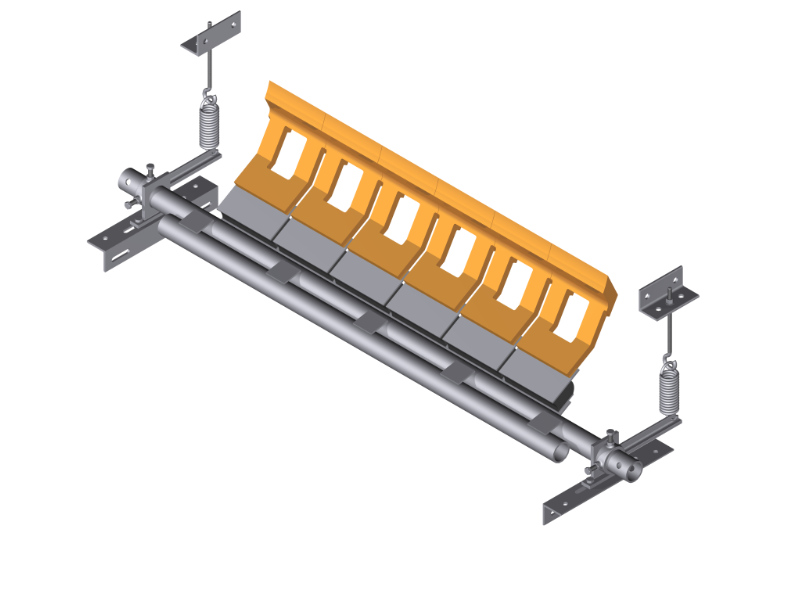

Basically, Air Blaster systems use strategically positioned compressors along the bulk material Flow Path, which blast compressed air in the right direction to prevent material build-up due to the various shapes that form within the material. The compressed air is usually stored in an air receiver, which maintains the air pressure at 6 to 7 Kgf/sq. cm. This compressed air is fed to the point of discharge through a 100/ 150 mm opening through operation of pneumatically controlled valves. The instantaneous but controlled release of compressed air into the stored material is at a faster rate than the material can absorb. Therefore, the material gets dislodged and flows on. Further, the nozzle installation is done in such a way that the air discharge is parallel to the surface, so that the reaction is not transmitted to the structure and is not detrimental to the process. The actuation of the Air Blaster can be done either manually or through Electronic Sequential Timer.

Schematic Diagram (Animated) of Air Blaster Installation

in Cement Pre-Heater :

Industries Catered:

Air Blasters are also used in very large number in the following plants and industries: –

- Cement plants – Kiln Inlet, Riser Ducts, Cyclones, Feed Chutes, Cooler

- Thermal Power Plant – Raw Coal Bunker, Coal Handling Plant (CHP), Coal Chutes, etc.

- Steel Plants – Sintering Plant (Hoppers), Coke Oven Plant, Refractory Plant, Raw Material Handling Plant, etc.

- Mines – Coal, Lignite, Iron Ore, etc.

- Coal Washeries – Transfer Chute, Bunker/ Hopper

- Paper Industries

- Sugar Industries

- Chemical Plants

- Fertilizer Plants

- Food & Pharmaceutical Industries

The Advantages of MM Airblaster

The Advantages:

- MM Air Blaster operates without interrupting the plant operation, thus avoiding production loss.

- MM Air Blaster operation will not affect the structure and surface.

- MM Air Blaster ensures increase in production by optimum capacity utilization of hopper/ bunker. Further, it also reduces the running and maintenance cost of material handling system (conveyor belts) and also saves power.

- MM Air Blaster can be services without dismantling the Blaster.

- MM Air Blaster works on plant air and no specific quality of instrument air is required. However, in case where plant air is not available at site, a portable compressor is sufficient.

- Spring loaded piston design helps in mounting the Blaster in any position.

High Temperature Applications:

Temperature Range: Up to 1200 °C

- Kiln Inlets

- Cyclones

- Coolers

- Rise Ducts

- Feeding Chutes

- Many more…

Low Temperature Applications:

Temperature Range: Below 80 °C

- For any powdery or granular material

- Silos

- Hoppers

- Bins

- Many more…

Maintenance & Services:

MM Air Blaster is very easy and convenient to maintain. There is no need to bring down the Blaster for servicing. It can be easily serviced from the point directly where it is installed. Maintenance tasks may include :

- Checking the mounts to make sure they are secure

- Clearing the air inlet for the device to recharge more easily, and

- Checking the Rubber O-Rings and Gasket for wear and tear

- Checking the lubricator for continuous lubrication, to be filled with oil.

- Checking the seals for any Air leak.

Well-qualified and dedicated engineers take care of our maintenance and service department. Impeccable installation standards and timely rendering of services are our trade marks in this market. Our product quality, marketing efforts and responsive service focus on customer satisfaction, which have brought us accreditation of ISO and CE.

NOZZLES DESIGN

High Temperature Nozzles

To ensure prompt delivery and quality product (Castings), MM Overseas (India) started in-house manufacturing of various grades of heat & corrosion-resistant castings, making nozzles of different type for different applications. We make high quality SS 310 casting nozzles, which are suitable to withstand the high temperatures and have long life. The different type of nozzles we produce are :

Air Blaster System Installations in Cement Plant

For The Brochure Please Download : H E R E